Hail Resiliency Curve Testing for PV Modules

Testing to failure is standard practice for glass reliability engineering. By applying these principles to solar panels, RETC and its sister company, VDE Americas, aim to solve a Texas-sized hail vulnerability problem.

Recent experience has shown that the technical due diligence community must do a better job of adapting solar farms to withstand the severe weather risks associated with a warming climate. In a review of claims data, climate insurance provider kWh Analytics has estimated that hail accounts for 6% of solar project insurance claims but more than 72% of losses by dollar amount. Moreover, hail-related solar project losses incurred since 2018 have exceeded $600 million—in the state of Texas alone.

As the leading state solar market in the most hail-exposed country in the world, Texas has emerged as the ultimate proving ground for PV technology climate resiliency. Solar project hail loss events in the Lone Star State have reached an unsustainable frequency and scale, putting a roadblock in the path of our collective efforts to avert a global climate crisis. However, if industry stakeholders can design PV modules and power systems capable of weathering severe convective storm environments in Texas, these resilient assets will provide a solid foundation to support power sector decarbonization as part of a global energy transition.

To prevent catastrophic hail losses in Texas, utility-scale solar farms must be able to withstand the ≥45-mm (≥1.77-in.) hail events likely to occur within an asset’s operational lifetime. Survival under these extreme conditions of use not only requires climate-adapted operational strategies—such as state-of-the-art hail monitoring and tracker stow capabilities—but also the availability of proven hail-hardened PV modules. To support the development and procurement of truly differentiated product designs, RETC and VDE Americas have partnered to introduce the Hail Resiliency Curve Test program—the industry’s first true measurement system dedicated to the development of hail-hardened solar assets.

Why pass/fail testing is failing now

In 1975, U.S. government-sponsored work began in earnest to develop cost-competitive PV module designs capable of supporting a large-scale terrestrial solar market. As part of the Flat-Plate Solar Array (FSA) Project, which ran from 1975 to 1986, the Jet Propulsion Laboratory (JPL) and the California Institute of Technology developed ballistic-impact testing techniques still used today to simulate and study the effect of hail on solar panels. As early as April 1978, these researchers described the process of subjecting commercially available PV modules to 25-mm (1-in.) simulated hailstones, identified in conference proceedings as “frozen ice spheres projected at terminal velocity,” and steel balls applied by gravity drop.

JPL’s groundbreaking work on the FSA Project was foundational to the development of the durability tests and performance standards that enable modern PV modules to withstand decades of field exposure. Analyzing probabilistic failure modes, the project’s reliability engineers defined many design qualification and product safety tests still relied upon today. To this day, we can still see JPL’s imprint on PV module ballistic-impact testing standards in the 50-mm (2-in.) steel ball drop test in IEC 61730 and the 25-mm (1-in.) freezer ice ball test in IEC 61215.

The fact that simulated hail testing standards derived from the FSA Project have largely served the industry well for more than 40 years speaks to the quality of the reliability engineering work done in the process of bringing a space-age technology down to Earth. Cracks in this foundation emerged only recently due to a perfect storm of solar technology and market trends.

On the technology front, solar panels have gradually become less hail resistant over time as manufacturers have pushed the value-engineering envelope with the introduction of ever-larger PV modules, often made with the thinnest possible front glass to control weight. With regards to markets, utility-scale solar project development activities have increased exponentially in the most hail-exposed region of the world—specifically, a distinct “hail alley” that extends north out of Texas along the eastern flank of the Rocky Mountains.

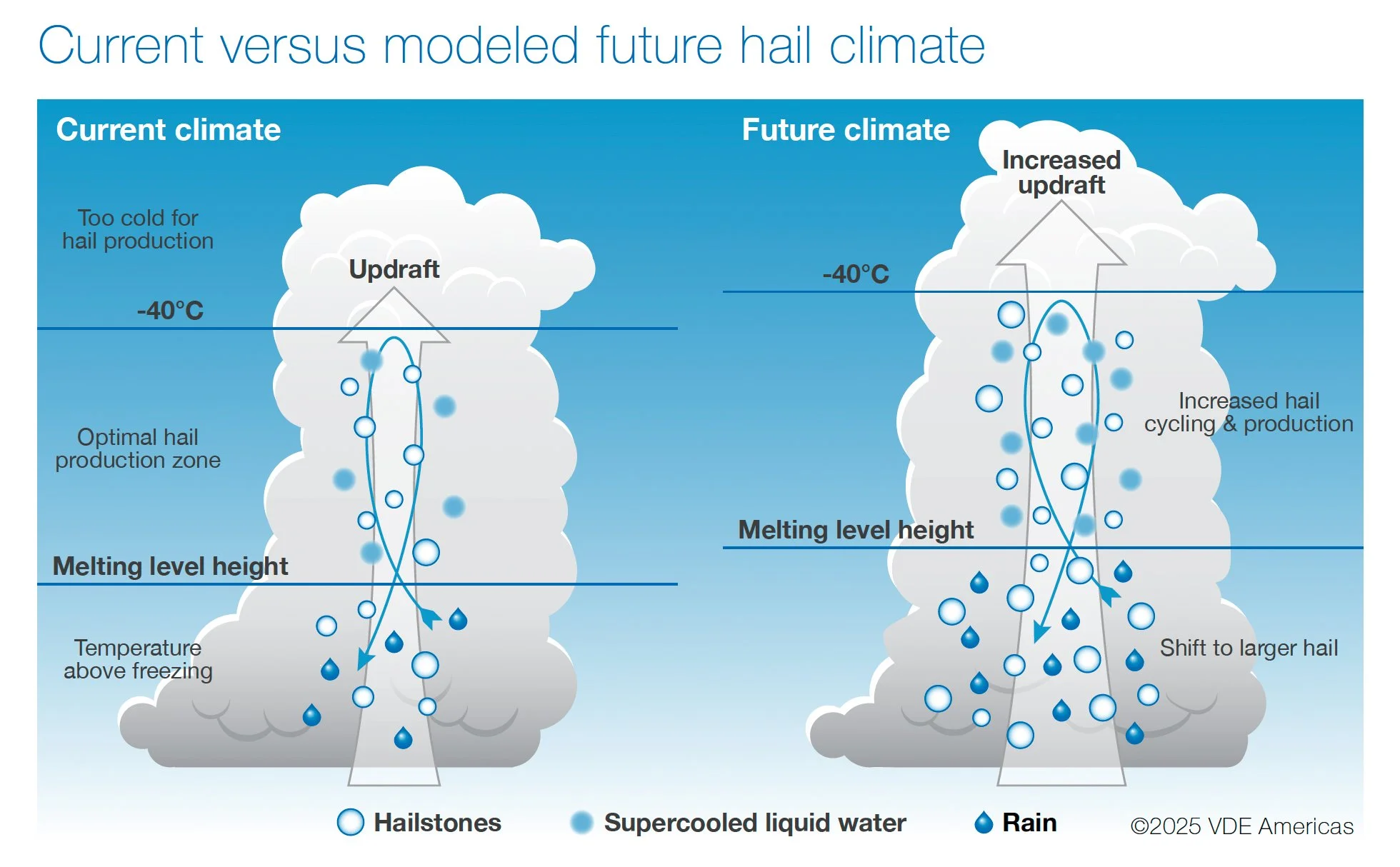

As if these intersecting trend lines were not enough cause for concern, climate scientists believe the effects of human-caused climate change have generally increased severe convective storm risk over the decades since JPL’s reliability engineers developed the industry’s prototypical PV module hail testing standards. This is the stage upon which the now-infamous $70 million Midway Solar Farm catastrophic hail loss event took place in May 2019, the shock waves of which still reverberate in solar insurance markets.

Climate models generally point to an increase in the annual number of hail days favorable to very large hail over the central and eastern United States.

Genesis of financial hail loss modeling

After the Midway Solar Farm made headlines, resetting the solar insurance market almost overnight, Wells Fargo engaged VDE Americas, a technical advisory firm that has supported the financing of over $15 billion in operating solar and energy storage assets, to help the tax-equity investor quantify its portfolio-level hail risk exposure. “At the time, I thought this was a two- or three-week project,” recalls John Sedgwick, co-founder of VDE Americas. “Instead, it has been a five-plus-year Ph.D.-led voyage of discovery.”

Under the direction of Dr. John T. Allen, one of the world’s foremost authorities on severe hail climatology, and Dr. Peter Bostock, an expert in solar engineering, physics, and financial modeling, VDE Americas developed science- and engineering-based meteorological and financial models that allow for site- and technology-specific hail risk assessments. RETC’s beyond-qualification ballistic-impact testing data was critical to these efforts.

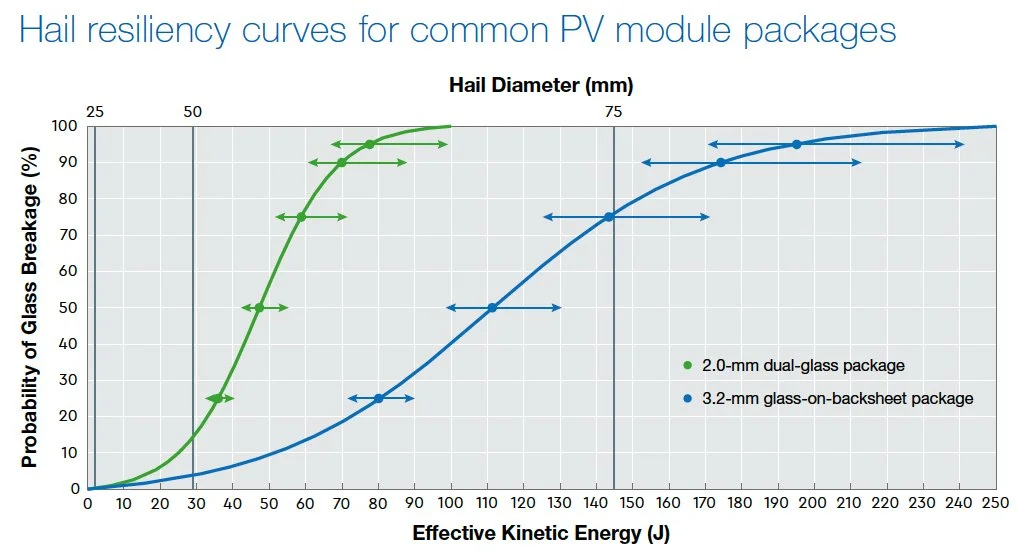

“Because our companies are both part of the VDE Group, one of the largest technology organizations in Europe, RETC was able to share with us anonymized hail test data,” explains Jon Previtali, vice president and senior principal engineer at VDE Americas. “This hail-impact test data provides comparative hail resiliency curve profiles for common types of PV modules that feed into our financial loss models.

“Looking at RETC’s published hail resiliency curves, you can see that a PV module package with 3.2-mm [0.13-in.] front glass and a polymeric backsheet is roughly twice as strong—twice as resistant to hail damage, in other words—as compared to a typical bifacial PV module with a 2.0-mm [0.08-in.] dual-glass package. You can also see that the uncertainty bars associated with these comparative hail resiliency curves are quite large, which is an opportunity for improvement. If we can reduce uncertainty, we can improve the accuracy of VDE’s Hail Risk Intelligence.”

RETC originally published the comparative hail resiliency curves shown here in the 2023 edition of kWh Analytics’ Solar Risk Assessment. The relatively large error bars associated with these Weibull curves are a reflection of the fact that the source data are based on pass/fail testing data, with large steps in effective kinetic energy. By comparison, the new Hail Resiliency Curve Test Program captures more granular test-to-failure data, which will significantly reduce statistical uncertainty.

Break glass in case of emergency

In 2023, Previtali’s team determined that the industry’s growing hail vulnerability problem could only be solved by a return to fundamental reliability engineering principles. With this in mind, VDE Americas enlisted a glass reliability expert with experience supporting advanced product development efforts at Fortune 500 companies, including Apple and Tesla, to support the development a low-cost, high-accuracy hail resiliency curve testing program for PV modules.

“What really interests me as a glass reliability engineer,” says Mike Pilliod, president and chief technical officer at Central Tension, “are measurement systems that provide a statistically representative probability of failure. The use case doesn’t really matter. Automotive glass, cellphone displays, architectural glass, you name it. If you’re not breaking glass—and not testing a representative number of samples to failure—you’re not doing your job as a reliability engineer.

“After I started working with VDE’s hail team, I quickly realized that the solar industry has effectively relied on a one-size-fits-all type of product qualification test. You put a sample PV module in front of a hail gun, fire an ice ball at it, see what happens. If nothing breaks, which is almost always the case, the product has passed the test and is considered good to go in all operating environments and conditions of use.”

According to Pilliod, the simulated hail tests in IEC 61215-2 are not a rigorous measurement system. The problem with pass/fail testing paradigms, he explains, is that they stop too soon, “Okay, one module passed. But why did you stop? Keep going. Figure out where the sample fails. If you gradually increase kinetic impact energy and test a meaningful number of samples to failure, you can generate Weibull distribution curves that plot the probability of glass failure on a product- or bill of materials-specific basis with low uncertainty. Now you can stack these Weibull curves and compare them. Do the curves overlap? If not, you can be reasonably certain that there is a statistical difference in resiliency.”

Pilliod continues, “Using a robust test-to-failure measurement system, you can evaluate differentiated product designs and support market segmentation. Big floppy modules, to borrow a term from NREL [National Renewable Energy Laboratory], are a great solution for many solar markets, but these products are probably not designed with hail resilience in mind. PV modules intended for deployment in hail-exposed locations benefit from use of stronger, more advanced glass. Evaluating the value proposition associated with these advanced products requires a more advanced measuring system.”

Testing to failure leads to understanding

At the 2024 PV Reliability Workshop, hosted by the National Renewable Energy Laboratory, VDE’s Bostock first described the conceptual framework for a Weibull-based, test-to-failure program capable of informing solar project financial loss models and property damage mitigation efforts. Over the next 12 months, a VDE Americas-led product durability dream team—made of scientists and engineers with expertise in glass reliability, manufacturing quality, statistical analysis, and laboratory testing—developed, drafted, and successfully piloted a new PV module hail resiliency test protocol.

Earlier this year, RETC became the first testing laboratory in the world to offer VDE Americas’ aptly named Hail Resiliency Curve Test to customers. Designed to evaluate solar panel resilience to hail damage, the test-to-failure program uses calibrated air guns to shoot progressively larger ice balls, a laboratory proxy for naturally occurring hail, at progressively higher speeds and impact energies until glass breakage occurs. Importantly, the test program provides a robust statistical representation of what happens during real-world events.

During a severe hailstorm, individual PV modules are subjected to a range of hail sizes and impact velocities. These numerous and varied impacts occur across different module areas—namely, center, edge, and corner regions—that have different resiliency characteristics. Basic pass/fail tests invariably characterize PV module hail resiliency as a simple step function, which cannot capture the complexities of a real-world hailstorm event.

“A primary benefit of VDE’s Hail Resiliency Curve Test program is that it smooths out the steps in the hail resiliency characteristics the technical due diligence community relies upon,” explains Previtali. “Risk advisers, insurers, and others need to understand the relationship between glass fracture and kinetic impact energy as a continuous probability distribution function. Our new testing program accomplishes this by testing a full pallet of samples to failure, with randomized impact locations across different module regions, enabling statistically meaningful comparisons between different module designs and installation configurations.”

“The solar industry has long required a more sophisticated approach to hail testing, one that goes beyond legacy pass/fail techniques,” says Cherif Kedir, RETC’s president and CEO. “The Hail Resiliency Curve Test fills a critical knowledge gap by providing our customers with actionable data to support the design or procurement of hail-hardened products suitable for deployment in hail-exposed locations.”

Proven hail resilient by design

As the first testing laboratory to offer VDE’s Weibull-based, test-to-failure protocol for hail, RETC is uniquely positioned to help manufacturers develop and validate differentiated PV module designs prior to market entry. Early adopters of VDE’s ground-breaking Hail Resiliency Curve Test program range from well-established publicly traded companies to insurgent venture-backed startups, representing every segment of the PV module manufacturing landscape.

The Hail Resiliency Curve Test provides manufacturers with unprecedented visibility into solar panel performance in parts of the world exposed to high hail risk. Specifically, this testing program allows companies to optimize hail-hardened PV module designs, while providing downstream customers, insurers, and technical advisors with reliable risk assessment and mitigation data.

“We are using the Hail Resiliency Curve Test to qualify potential glass suppliers and evaluate the business case for standardized versus differentiated product designs,” says Chad Medcroft, senior vice president of global energy services at Erthos. “As the inventor of Earth-mounted solar, we believe the best way to mitigate hail risk is to focus on module resilience rather than rely on tracker operation, which runs counter to convention. Extensive third-party testing can improve customer and insurer confidence in our technology by validating its unique value proposition.”

The solar industry’s collective response to catastrophic loss events is one of the silver linings associated with an increase in severe weather damage. “Six years ago, virtually all solar trackers were designed to stow flat in response to high-wind events,” recalls Brian Grenko, president and CEO of VDE Americas. “That all changed after the technical due diligence community started working with manufacturers and asset owners to more accurately quantify hail damage potential and mitigate risk via product design and system operation improvements. Today, more and more trackers are designed to stow at a maximum tilt angle for both hail and wind, and more and more module companies are developing and commercializing hail-hardened solar panels.”

Though large-diameter hail is inevitable in some regions, large project losses are not. Informed by beyond-qualification testing data and calibrated radar-observed meteorological data, solar project financial hail loss models and forensic investigations consistently indicate that properly designed and operated solar farms can withstand the expected conditions of use in even the world’s most hail-exposed locations. The margin of design safety will only increase over time, as project stakeholders learn how to automate reliable hail monitoring and stow defenses and module companies master the art of cost-effectively hardening solar modules against hail.

RETC’s test-to-failure program for solar panels uses freezer ice balls manufactured to IEC standards as a laboratory proxy for naturally occurring hail. [Credit: RETC]

Knowledge is power!

This article originally appeared in the 2025 edition of RETC’s annual PV module technology report.