Forensic Analysis of Solar Asset Performance

In-field forensic investigations allow project stakeholders to identify the root causes of PV module underperformance in real-world applications.

According to kWh Analytics, a leading solar risk assessment and mitigation expert, project underperformance is a genuine and growing concern. In the 2021 edition of its Solar Risk Assessment report, kWh Analytics warns that “1-in-8 [solar] projects persistently underperform their downside (P99) scenario over multiple years.” While most solar projects meet performance expectations, kWh Analytics notes that persistently underperforming systems threaten solar loans as an asset class.

Forensic analysis is a detailed investigation to establish the root cause of PV system underperformance. Inverter failures or inaccurate production estimates are often—but not always—to blame for actual or perceived system underperformance. If PV module health is suspect, in-field forensic investigations, conducted before or after the commercial operations date, are an invaluable performance-risk-mitigation tool.

In-field forensic investigations are an invaluable performance-risk-mitigation tool.

BASELINE ASSESSMENT

One of the best ways for project stakeholders to reduce project risk is to engage a qualified third party to conduct a baseline module health assessment during project commissioning. Because it captures high-quality measurements before commercial operations, a baseline forensic assessment provides both short- and long-term benefits over the operating life of a PV power system.

In the short term, a baseline commissioning assessment improves the accuracy of system performance estimates. Project financiers and insurers rely heavily on probabilistic estimates of PV asset performance in the field. Many PV systems are debt-financed based on the assumption that the plant’s operating cash flow will service the loan. Therefore, improving the accuracy of system performance estimates ultimately reduces the risk of loan default.

It is challenging to process a warranty or insurance claim without high-quality baseline measurements captured at the beginning of the project lifecycle.

Over the long term, baseline commissioning assessments also benefit system owners and operators. Processing a warranty or insurance claim without high-quality baseline measurements captured at the beginning of the project lifecycle is challenging. In addition to determining the initial module health status, a baseline commissioning assessment is helpful for documenting site-specific risks associated with the environment, design, or installation quality.

DAYTIME EL TESTING

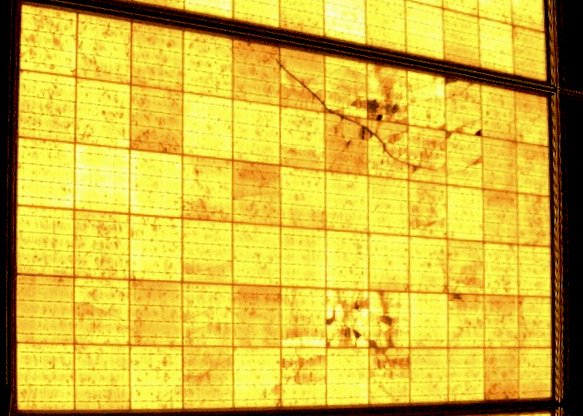

Electroluminescence (EL) testing uses a special camera system to document the light emissions that occur when an electrical current passes through PV cells. EL testing has a long history in the laboratory, where it is used to detect a wide range of hidden module defects. Once relegated to controlled indoor environments, EL testing is increasingly common in field forensic investigations.

RETC conducts daytime EL testing for field forensic investigations. Daytime EL imaging is a technically advanced methodology that provides two distinct benefits over earlier approaches. First, this EL testing methodology allows technicians to test modules in situ, which expedites the testing process and eliminates cell damage due to module removal and handling. Second, daytime EL testing eliminates the need to test modules in the dark of night, further improving safety and throughput.

The results of in-field EL testing are valuable for identifying major manufacturing defects, off-site shipping and transportation damages, on-site material handling or installation damages, or damages resulting from severe weather events such as hail, wind or snow. Project stakeholders use these images to identify cell damage that can lead to thermal nonconformities, hot spots and future module underperformance.

When adequately documented and reported, third-party EL images can help settle warranty and insurance claims. Unlike aerial infrared (IR) imagery, which identifies only the potential locations of performance issues, daytime EL investigations elucidate the root causes of underperformance. These findings benefit project stakeholders by expediting issue resolution and minimizing production losses.

PREDICTIVE MAINTENANCE

Third-party field performance forensics are especially practical when coupled with a robust monitoring platform and predictive maintenance protocols. As PV modules age, fielded assets are at increased risk of underperformance. Cell microcracking often does not impact module performance when modules are new, but that is not necessarily the case as systems age. After 5 or 10 years in the field, some modules continue to perform as expected, whereas others suffer from accelerated degradation.

Once individual cells start behaving differently, that thermal mismatch has the potential to create a vicious circle that leads to further mismatch.

“In our PV performance monitoring program, thermal mismatch is something that we monitor closely,” says Dr. Ralph Romero, senior managing director of digital infrastructure advisory services at Black & Veatch. “Once individual cells start behaving differently, that thermal mismatch has the potential to create a vicious circle that leads to further mismatch. Thermal mismatch resulting from cracked cells or other causes needs to be closely monitored as it can lead to substantial PV system underperformance.”

Differentiating between “good” and “bad” modules is not a simple matter, especially in systems deployed after the US Department of Commerce enacted its policies on antidumping and countervailing duties (AD/CVD). Large projects that appear to have a single module supplier may in fact integrate modules manufactured using cells sourced from a dozen different vendors. Given that each bill of materials (BOM) is unique, each has a different risk profile.

“It is important to have a predictive maintenance protocol in place,” explains Romero. “We are aware of digital monitoring platforms that are very good at identifying potential root causes of underperformance, that can do so at a granular level in both portfolios of distributed assets and large utility systems.

“If we suspect that PV modules are underperforming and the root causes are not identifiable through performance monitoring,” Romero continues, “we can ask the forensic analysis team to identify the root causes of underperformance. With this information in hand, we can develop an action plan based on a cost-benefit analysis of potential remediation measures. In the process of engineering a cost-effective solution that immediately improves system performance, we can also take steps to prevent the recurrence of underperformance moving forward.”

For more information see:

RETC’s 2022 PV Module Index Report