RETC’s Hail Durability Test Program

In response to a recent crisis of confidence, RETC introduced a dedicated beyond-certification test program designed to address the risks associated with large-diameter hailstones.

In May 2019, hail damaged some 400,000 modules at the Midway Solar generating facility in West Texas, resulting in a previously unimaginable $80 million in insured losses. Recognizing that basic certification test standards are inadequate to identify and quantify the project risks associated with hail, RETC developed its innovative Hail Durability Test (HDT) program.

By expanding upon existing UL and IEC standards, the HDT program helps project stakeholders better understand hail effects on PV modules in real-world applications. Here, we answer some frequently asked questions about RETC’s proprietary HDT sequence and classification system.

WHAT ARE THE BENEFITS OF THE HDT PROGRAM?

The vast majority of modules are unscathed by the basic ballistic impact tests found in Underwriters Laboratories (UL) and International Electrotechnical Commission (IEC) standards. UL 1703 subjects modules to the impact of a 50-millimeter (2-inch) steel sphere dropped from a height of roughly 130 centimeters (51 inches); in rare cases, the resulting 6.78-joule impact will result in cell damage. Virtually all module designs pass the hail test in IEC 61215-2, which subjects modules to 11 impacts of a 25-millimeter (1-inch) ice ball traveling at its terminal velocity; this basic product certification test results in a modest impact force of 1.99 joules.

Minimum certification test standards are inadequate to characterize large-diameter-hail risks.

To differentiate product designs, RETC’s HDT program expands and improves upon UL and IEC requirements in meaningful ways. First, the HDT program subjects modules to higher kinetic impact energies, ensuring that the test standard better reflects the risk posed by hail over a 25- or 30-year operating life. Second, RETC designed the program to thoroughly investigate a range of possible outcomes, which provides valuable data for probabilistic analyses. Third, the test sequence is not limited to ballistic impact testing; it also includes thermal cycle and hot-spot tests to reveal potential long-term module degradation modes.

By exposing modules to severe, very severe and extreme hail strikes, the HDT sequence effectively investigates ballistic-impact resistance at the threshold of damage, just over this threshold and at material failure. RETC’s program ensures consistent ice ball quality, repeatable impact velocities and precise kinetic impact energies to maximize stakeholder confidence in the test results.

Testing to failure allows stakeholders to compare and contrast performance under severe conditions.

WHAT IS THE BASIC SCOPE AND STRUCTURE OF THE HDT?

A flow chart for RETC’s extended HDT sequence is broken out below:

To start, RETC characterizes the initial condition of eight randomly selected test samples based on EL testing, visual inspection and maximum power measurement.

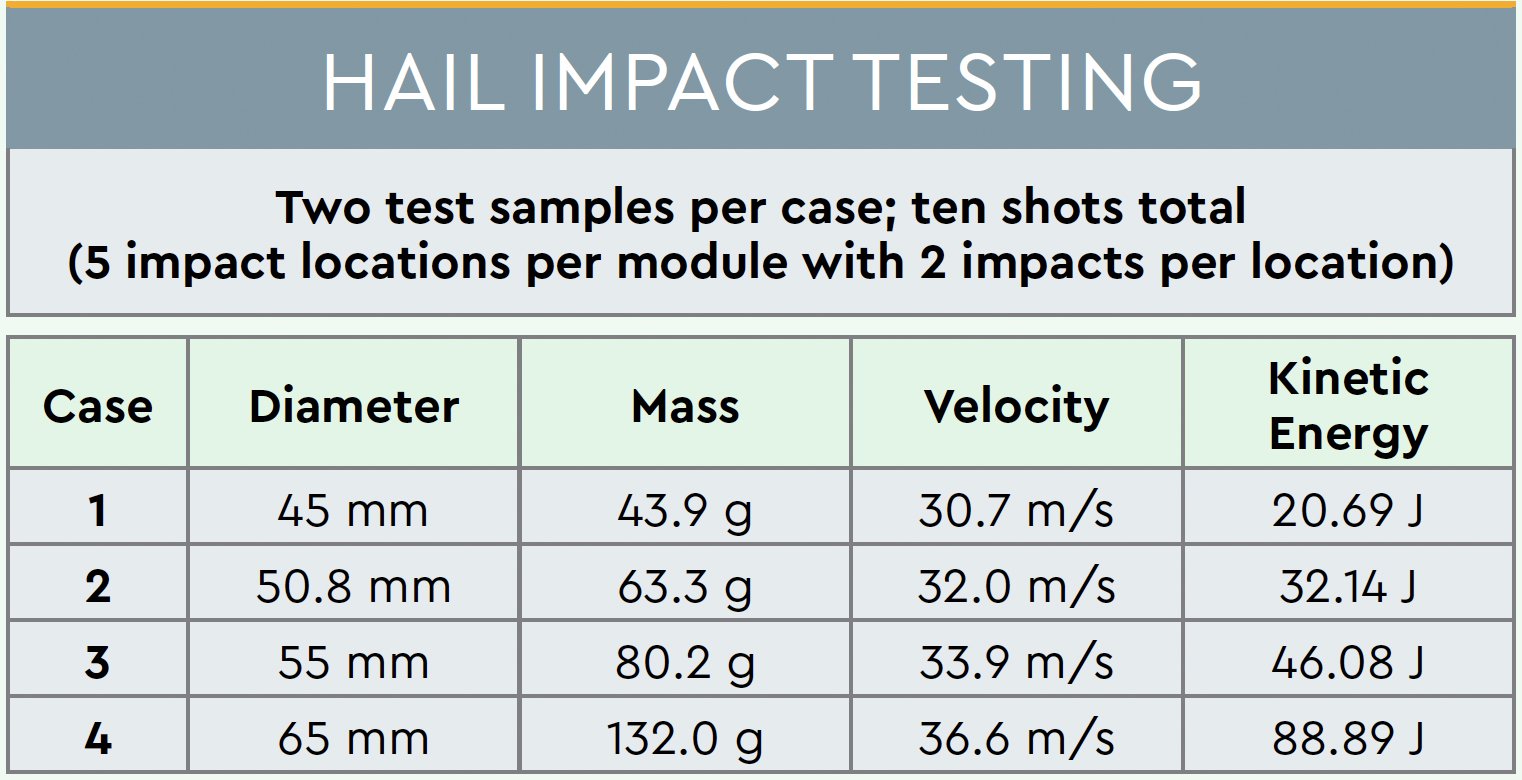

Next, RETC subjects each test sample to ten hail impacts at five locations. To understand how impact severity affects outcomes, we divide the eight modules into four test cases that vary based on hailstone diameter, mass, impact velocity and kinetic energy.

After exposing each two-module test case to 10 strikes from an iceball of a specific diameter—45 millimeters (1.8 inches), 50.8 millimeters (2 inches), 55 millimeters (2.2 inches) or 60 millimeters (2.6 inches)—RETC characterizes the post-hail condition of each test sample.

We then put all eight modules into an environmental chamber and cycle the temperature 50 times from 85°C on the high end to -40°C on the low end, as detailed in IEC 61215.

After the TC50 exposure, we characterize the post–thermal cycle condition of the modules.

The penultimate step in RETC’s HDT sequence is to subject the test samples to the hot-spot endurance test found in IEC 61215. This test evaluates how the modules withstand hot-spot heating effects under worst-case shading and operating conditions.

After hot-spot testing, RETC characterizes the final condition of the test samples based on EL testing, visual inspection and maximum power measurement.

After processing these results, RETC characterizes product designs according to a hail-impact classification system from Class A (best) to Class D (worst). Conceptually, RETC’s PV module hail-rating system is similar to PV system fire-rating classifications, which are essential to product selection and qualification.

WHO USES THE INFORMATION CONTAINED IN AN HDT REPORT?

The detailed information contained in a completed HDT report is helpful to module manufacturers, insurance companies, investors, developers and independent engineering firms. The resulting final report analyzes the collected module characterization data, identifying and quantifying uncritical, critical and very critical abnormalities.

Fielding increasing numbers of higher-capacity solar projects in locations around the globe is not without risk. Mitigating site-specific risk requires the strategic application of products and technologies. For example, hail-hardened module and system designs mitigate project risk in hail-prone regions like West Texas.