Reliability Lessons from Texas

Based on its sheer size and average sun hours, Texas is blessed with the nation’s best solar resource—it is also bedeviled by extreme weather risks.

The solar boom in Texas illustrates the extreme highs and lows of life on the solarcoaster. On the one hand, Texas is home to Invenergy’s 1,310 MW Samson Solar Energy Center, the largest solar project in development in the US today. On the other hand, Texas is also home to the 182 MW Midway Solar generating facility in West Texas, which infamously experienced large-scale losses due to hail damage.

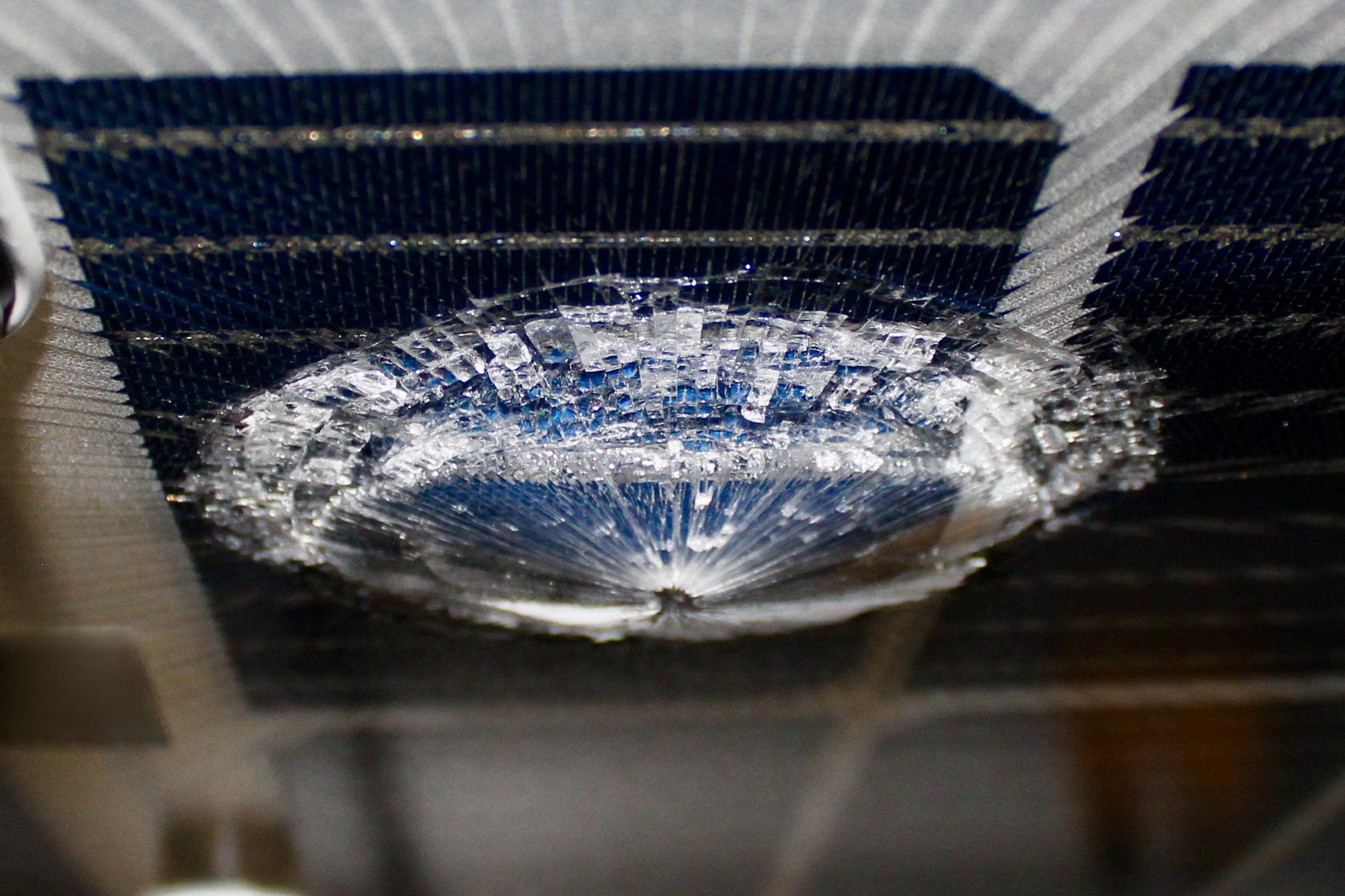

Depending upon the source, the insured losses associated with the Midway Solar farm were somewhere between $70M to $80M, likely the largest solar claim to date. While the impacts of this single event in May 2019 are still rippling throughout the industry, collectively we have learned some valuable lessons.

HAIL TESTING

The basic hail assessment test for product certification is based on 11 impacts of a 1-inch hailstone traveling at terminal velocity. This minimum testing standard is insufficient to assess the risk of hail damage in hail-prone regions, which include Texas, the central region of the U.S. and other locations around the world. As module form factor increases and front-side glass thickness decreases, hail is potentially more impactful both in terms of glass breakage and cell cracking.

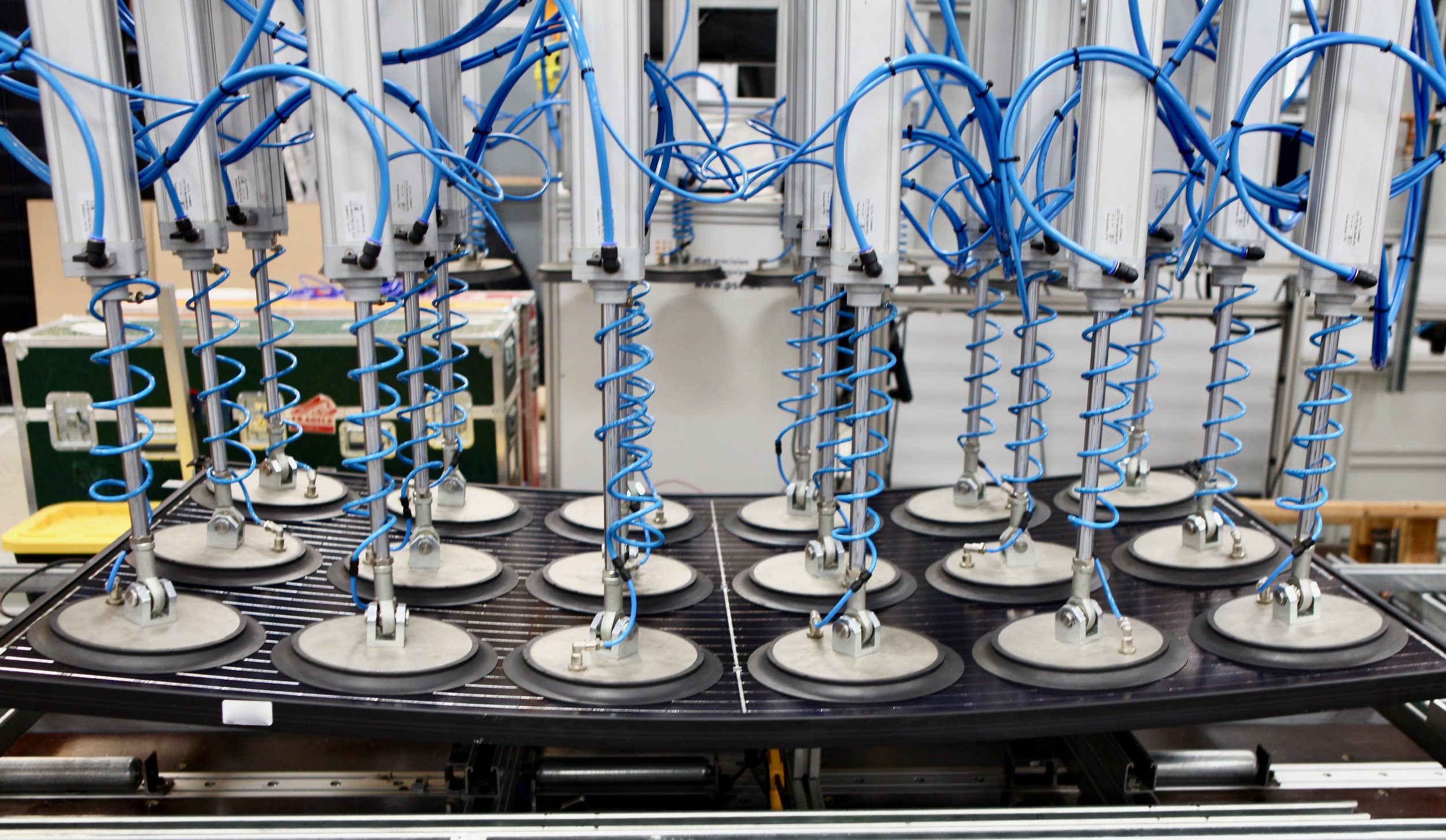

To address this gap, RETC developed the Hail Durability Test (HDT), a beyond-qualification test program designed to better characterize project risk. The HDT uses enhanced stress test criteria to simulate larger-diameter hailstones. It can also characterize the effectiveness of trackers with defensive stow modes that rotate modules to a high tilt angle, effectively minimizing opportunities for direct strikes.

Greg Beardsworth, Nextracker’s director of product management, says, “Working in partnership with RETC, we have seen a massive improvement in hail-impact survivability at high-tilt angles. The test data indicates that stowing modules facing into the wind at 60° during a hailstorm can increase the survivability of PV panels from 81.6% to 99.4% based on severe weather data.”

While RETC’s preliminary HDT results are promising, additional research is needed and ongoing. Henry Hieslmair, PhD, principal engineer for solar at DNV, notes, “The question we need to answer is not whether or not glass breaks with 25mm hail. The hail damage of greatest concern is whether cells begin to break at 35mm or 45mm hail sizes. The type of hail testing that RETC is pioneering is needed by the industry.”

HIGH WIND

From Gulf Coast hurricanes to West Texas wind farms, Texas is also one of the regions of the country where solar farms experience high wind speeds. In these highwind regions—such as Florida, Hawaii, New Jersey and North Carolina—the mechanical integrity on the negative side of the module with the uplift is extremely important. The mechanical strength ratings for many modules are very low relative to the wind loads associated with a hurricane.

DNV’s Hieslmair would also like to see more reliance on enhanced stress testing for high-wind areas. “The dominant test standard for module mounting on trackers, UL 3703, does not test for cell cracking and module power degradation,” he explains. “DNV is scrutinizing the gap between typical IEC-type static/dynamic mechanical loading tests and the UL 3703 test standards for tracker mounting. Of great concern to clients is that the UL test also lacks the subsequent thermal cycling and humidity-freeze cycling required to open the cell cracks to observe them at maximum power in an electroluminescence tester.”

INSURANCE

One of the biggest lessons coming out of Texas is that the days of relatively inexpensive insurance with broad coverage are over. Prior to the large insured losses at the Midway Solar farm—as well as other large catastrophic losses—it was possible to buy affordable solar project insurance coverage that effectively transferred risk from the owner to the underwriter. This is no longer the case, as insurers have increased pricing and premiums and introduced sublimits and exclusions.

Navigating these waters requires more sophisticated insurance products and approaches. In today’s market, project stakeholders need to focus on eliminating losses before they happen, in which case insurance operates more as a credit support tool based on net capital expenditure. This approach to insurance requires extensive technical due diligence and beyond-certification testing data.